Research Experience for Undergraduates (REU)

REU in Functional Nanomaterials and Nanoscience

Basic Information about REU 2012

Wednesday at One Schedule

This program, funded by the National Science Foundation, provides opportunities for undergraduate students to carry out research projects during a 10-week summer program at the University of Nebraska in Lincoln, Nebraska. The research will focus on the fabrication, characterization and properties of nanoelements (monolayers, clusters or wires), nanostructured materials, and the response of materials at the nanoscale. This interdisciplinary program involves researchers from six departments across two colleges.

The program will have individualized research projects in a multidisciplinary setting, with the projects culminating in a Research Symposium for campus-wide undergraduate researchers. The research in which the undergraduates will participate has significant ramifications in a number of areas, notably in the development of materials for biomedical applications, sensors, electronic or magnetoelectronic devices, or mechanical systems. The program will focus on developing the student?s abilities to work independently in a research environment, and encourage creativity and problem solving skills. The students will create new materials via a variety of synthesis/fabrication techniques, and characterize the resulting structure and properties using a variety of techniques.

The program will promote careers in research, exposing a broader spectrum of students to a research environment, and increasing the participation of underrepresented groups in research. The project also includes a professional development component that will expose the students to the broader impact of science and technology on society. Included will be aspects related to the transfer of high-technology ideas and products to the commercial sector.

Students interested in the program can apply at http://www.unl.edu/summerprogram/ starting on December 8th. Eligible students include all undergraduate students with at least two years of college majoring in math, science, or engineering at any US college or university who are US citizens or permanent residents.

Mentors and Projects Include:

Project Name: Exploring Mechanical Behavior of Metal-Organic

Mentor: Dr. Li Tan, Engineering Mechanics

Material design is one of the key frontiers in nanoscience research. Knowing the relationship between the material property and molecular structure can guide and sometimes facilitate the design. Our motivation in this summer project is to probe this relationship using 7 crystals of well-defined structures. The selection of metal-organic frameworks (MOFs) as the test bed is because they have well-defined shapes and clear molecular structures. In contrast to many inorganic or metallic structures, the synthesis of MOFs is quite flexible. Under different reaction conditions, the same exact reactants can be packed into highly porous crystals with distinct stacking or topology. Such flexibility in structural regulation allows us to gain knowledge about the relationship between molecular stacking and mechanical properties. Overall, the research objectives are to: 1) probe the mechanical properties of MOFs with nanoindentation and 2) link the properties with the molecular stacking. The REU student will work with chemists in the fabrication of MOFs, and then conduct the nanoindentation experiments. Of particular interest is to link the nanoscale porosity to both the hardness and modulus determined by nanoindentation.

165.jpg)

Project Name: Optical Hall-effect characterization of high mobility epitaxial graphene

Mentor: Dr. Mathias Schubert, Electrical Engineering

The extreme ability of free-standing graphene layers for de-facto inertia-less acceleration of free charge carriers offers the key to nearly-unlimited speed, terahertz (THz) frequency enabling, Ångström scale transistors. While contemporary CMOS technology is stretched to its scaling limits, exploitation of epitaxial graphene - if well controlled and understood - could achieve a substantial part of what is required to supplant CMOS technology. Epitaxial graphene could trigger a revolution in high-speed electronic devices that can fuel the major world industry–electronics–for its next growth cycle. Highest-quality epitaxial graphene growth can be achieved on silicon carbide substrates, for example. Further advances are on halt, however, because so far epitaxial graphene is affected by substantially deteriorated free charge carrier properties. Traditional electrical investigation of the free charge carrier properties are obscured by the suspected multiple free charge carrier channels within the graphene layer as well as within the substrate. Understanding and control of the effects of the substrate onto the free charge carrier properties in epitaxial graphene can provide the key to a new generation of THzclocked graphene-based large-scale electronic device technologies.

We propose to investigate the influence of the substrate properties onto the free charge carrier properties in epitaxial graphene. In particular, we are studying and understanding how the substrate surface polarity of non-polar substrate materials influence the free charge carrier 8 properties in epitaxial graphene. Our unique approach comprises non-contact and non-invasive Optical Hall-effect characterization. The proposed research accompanies ongoing activities within the research group of Dr. Schubert, and may lead to breakthrough advances in understanding of the electronic properties of epitaxial graphene. The Schubert group at UNL has recently developed the new instrumental approach of the Optical Hall-effect with support by NSF under DMR 0922937 “MRI: Development of an Optical Hall Effect Instrumentation for noncontact Nanostructure Electrical characterization”. This technique permits non-contact, noninvasive free charge carrier profiling and uniquely tackles the great present challenges in achieving device-grade epitaxial graphene. The Schubert group closely works with collaborators at Naval Research Laboratory and Cornell University in preparation, structural, electrical, and optical characterization of epitaxial graphene materials, and their device incorporation. The ongoing research offers exciting opportunities for undergraduate students to get involved in state-of-the-art research topics and instrumentation, in learning about contemporary materials science challenges, and for participating in an active research area. The graduate students will closely work with graduate students, postdocs and research faculty on this topic. Training for operation of instrumentation will be provided, and a selected set of samples will be investigated. Data analysis skills will be taught to the undergraduate student and involvement in reporting and publication activities will be organized.

Project Name:New Nanoclusters for Catalysis

Mentor: Dr. Barry (Chin Li) Cheung, Chemistry

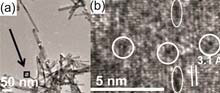

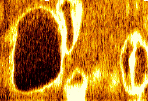

Figure 1

TEM images of ceria nanorods. The arrow and box

indicate the approximate zoomed in area of interest, shown

in (b). Here, oxygen vacancy defects (OVDs) are shown,

including point (circles, O) and linear (ovals, 0).

This project focuses on the synthesis of rare earth-based nanomaterials and researches the use of their electronic structures and nanosized geometry to create functional electronic materials and catalysts. Various rare earth nanomaterials with controlled shape, size, and compositions have been synthesized, such as ten different rare earth hexaboride nanoobelisks and nanowires [3,4,5] and ceria nanorods [6]. The Cheung lab’s recent focus is on cerium oxide nanorod catalysts with engineered oxygen vacancy defects through doping with a low concentration of metal clusters and activation under low vacuum (Fig. 1) [6]. A specific REU project in the Cheung lab is to develop a class of catalyst; metal clusters supported on cerium oxide nanorod supports selectively converts bio-based chemicals including cellulose, glycerol and other types of bio-based carbohydrates into commercially value-added chemicals. For example, glycerol is a by-product of the production of biodiesel via transesterification of fatty acids. With U.S. biodiesel production at an all-time high, the biodiesel industry is facing an exploding supply of glycerol (for example, 12.2 million tons were produced in 2008) [7,8]. It is imperative to find ways to efficiently convert this excess glycerol supply into valuable commodity chemicals to maintain the profitability of the biodiesel industry. Capitalizing on the lab's preliminary results, it is postulated that the cerium oxide nanorods decorated with tin oxide and palladium oxide lead to a highly effective oxidative catalyst for glycerol oxidation conversion to products such as lactic acid and glyceric acid with high selectivity at different pHs.

The REU student participating in this project will explore the basics in bio-based chemicals and heterogeneous catalysis. The student will learn and perform: 1) synthesis of ceria nanorods by the hydrothermal method and metal oxide cluster decoration using a self-reduction reaction; 2) structural characterization by electron microscopy and x-ray diffractometry; and 3) catalytic conversion reactions and yield evaluations using high pressure liquid chromatography coupled with mass spectrometry. The REU student will work alongside graduate students and interact on daily basis with Cheung. The student will participate in weekly meetings to discuss project progress and actively brainstorm research ideas.

Project Name: Biocompatible Surfaces from Three imensional Nanostructures

Mentor: Dr. Eva Schubert, Electrical Engineering

Project Name: Immobilization of Redox Proteins on Gold Nanoscaffolds for Enhanced Bioelectrocatalysis

Mentor: Dr. Rebecca Lai, Chemistry

The REU student in the Lai lab will participate in a research project which focuses on the design and fabrication of gold nanoscaffolds for immobilization of redox proteins such as myoglobin and cytochrome c. The study of direct electron transfer between immobilized redox proteins and the electrode surface is very important in the fields of bioelectrochemistry and bioelectronics [9]. However, despite the recent advances in protein immobilization strategies, the ongoing challenge is the maintenance of efficient electrical communication between the active site of the redox protein and the electrode surface [10]. Direct immobilization of redox proteins via the metal center on an imidazole self-assembled monolayer (Im-SAM) has been reported; however, the use of smooth gold electrodes is less advantageous [11]. The use of 3D gold nanoscaffolds with an Im-SAM will allow efficient immobilization of orientation-specific redox proteins, which could enhance the overall bioelectrocatalytic efficiency. While various Au nanoscaffolds have been developed for biosensing applications to date [12], a simple and costeffective method has yet to be realized. Here we propose the use of a colloidal crystal templating method which allows the preparation of a wide range of ordered micro- and nanoporous gold structures [13]. To generate the gold scaffold, we will first immobilize polystyrene beads on an electrode substrate, followed by electrodeposition of gold. The beads will be subsequently removed, leaving behind the 3D gold scaffold for SAM formation and protein immobilization (Figure 2). The effect of bead size, electrodeposition time and protein immobilization conditions on sensor performance will be

systematically investigated, with the goal of finding a set of conditions well-suited for bioelectrocatalytic detection of analytes such as hydrogen peroxide. In the 10-week REU period, the student will (a) learn to utilize polystyrene beads to generate gold nanoscaffolds (week 1-3), (b) study the effect of different parameters on protein immobilization (week 4-6), and (c) investigate the bioelectrocatalytic ability of the optimized

sensor (week 7-10). Through these studies, the student will receive training and exposure to basic electrochemistry and knowledge in biosensor design. The REU student will work closely with a graduate student or postdoctoral researcher in the Lai lab. The student must keep and maintain a laboratory notebook, which will be examined regularly by the supervising graduate student or postdoctoral researcher. The student will also

be required to participate in the weekly group meeting and submit a written report on their work at the end of the program

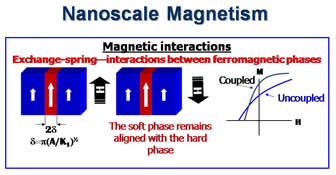

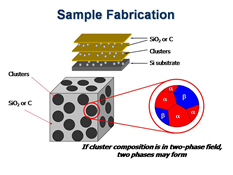

Project Name: Nanostructured high-energy permanent magnets

Mentor: Dr. Jeffrey Shield , Mechanical Engineering

High-energy permanent magnets are gaining increased attention because of their role in energy conversion devices necessary for wind turbine technology, hybrid and electric vehicles, and other high-technology applications. Magnetic interactions between hard and soft magnetic phases in nanostructured two-phase composites result in permanent magnet materials with significantly enhanced magnetic properties [15,16,17,18]. The primary challenge is to control the scale of the two phases to ensure exchange coupling. For several different alloy systems, we have shown that a combined processing approach involving both rapid solidification via melt spinning and mechanical milling enhances the magnetic performance. In this project, REU students will design new alloy compositions and use the combined processing to create highly homogeneous nanostructures with enhanced magnetic properties. The REU student will vary processing parameters such as alloy composition, wheel speed, and milling time, and study the materials using x-ray diffraction, electron microscopy, and magnetometry. In our experience, REU students readily learn these processing and characterization procedures.

Project Name: Understanding Cell Function and Properties Through Nanoindentation Studies

Mentor: Dr. Joseph Turner , Engineering Mechanics

Students in my laboratory will learn the fundamentals of scanning probe microscopes (SPM) including atomic force microscopes (AFM) and depth sensing indentation (DSI) instruments for nanoindentation. These techniques are essential tools used today for determining mechanical properties (e.g., modulus and hardness) of nanoscale materials. Current research is now focused on viscoelastic properties (e.g., storage modulus, loss modulus) through dynamic testing methods with particular interest on biological materials. Quantitative measurements and imaging techniques will be emphasized by training the students about the mechanics of how these instruments function. The students will also learn about relevant contact mechanics associated with these probes so that they are aware of assumptions used in the instrumentation for extraction of quantitative mechanical properties. The students will work with a graduate student mentor on the equipment to perform training of each measurement mode until they are at a level sufficient to use the instrument alone. Then the student will be assigned a material system (e.g,. bio-composite, biomaterial, specific biological sample, etc.) that they will use as their sample for their summer REU project. The projects will be tailored to materials currently being studied in my group. For example, previous undergraduates have studied cartilage, bone, and plant materials.

Project Name: Making Flexible and Translucent Polymer Solar Cell for Windows

Mentor: Dr. Jingsong Huang, Mechanical Engineering

Fig. 3 Pressure on the solar cells can deform the electrodes, causing the anode and cathode to contact through the thin photoactive layer (~180 nm), shorting the device. The hard nanoparticles prohibits contact, avoiding a short.

Organic solar cells (OSCs) are optoelectronic devices that convert solar energy directly into electricity and is one of the most promising clean and renewable energy sources to be used Figure 2. Fabrication of gold nanoscaffolds for immobilization of redox proteins. Template Assembly Electrodeposition of Gold Template Removal Protein Immobilization 5 for fossil energy replacement in the future. The power conversion efficiency of OSCs is already at a level (7~9%) [14] that competes with amorphous silicon solar cells. In addition OSCs offer promise to produce energy with lower cost per peak watt due to their low-cost fabrication process, more applications due to their light weight and flexibility and the opportunity to use them for building-integrated photovoltaics. For mass production of OSCs, their fabrication is by a fast and economical process with high-throughput, such as the continuous roll-to-roll manufacturing process. The critical issues in the roll-to-roll lamination process are how to form good electronic contact at the polymer/electrode interface for high PCE efficiencies and to obtain devices with good mechanical stabilty for high durability. One of the practical problems for laminated devices is the formation of short points under pressure induced by bending or impact. The shorts occur because the polymer photoactive layer is soft and there are spikes or protuberance on both electrode sides. Using nanoparticles with high hardness as spacers, shorting can be eliminated (Figure 3). The REU student will go through the process of fabricating OSC with and without spacers. This activity is expected to impress on students the many advantages of organic solar cell technology, including their low-cost materials and fabrication process, flexibility, translucence.

Project Name: Molecular Ferroelectricity at the Nanoscale

Mentor: Dr. Stephen Ducharme, Physics & Astronomy

These unique materials are the first ever two-dimensional molecular ferroelectrics, formed layer-by-layer into ultrathin crystals ranging from 1 nm to over 1000 nm thick. They exhibit many of the classic properties of ferroelectricity, the electric analog of ferromagnetism. However, their behavior during switching, the reversal of the electric polarization caused by an external electric field, are very different from other ferroelectric materials. We intend to probe the underlying cause of the unique switching properties of molecular ferroelectrics by studying the nanostructure, nonlinear dielectric properties, domain structures, and polarization dynamics.

The research group working on ferroelectric polymers consists of Professor Ducharme, distinguished Visiting Professor Vladimir Fridkin, a post-doc or two, several graduate students, and one or two undergraduate students. We collaborate closely with other research groups at UNL and around the world. Our group functions as a highly integrated unit, with each member making essential contributions to the study of these complex materials. The REU participant will be expected to work cooperatively with other members of the group and with collaborators, learning from other group members and offering your own results and insights from the laboratory work.

Project Name: Development of Low-Cost STM for Graphene Studies

Mentor:Dr. Axel Enders, Physics & Astronomy

One of the exciting fields of physics involves imaging surfaces with atomic resolution using a scanning tunneling microscope (STM). STM is an imaging method where an ultrasharp metallic tip is moved in a controlled fashion across a sample and the tunnel current - a quantummechanical phenomenon, is measured simultaneously. In 1986 Gerd Binning and Heinrich Rohrer were awarded the Nobel Prize in Physics “for their design of the scanning tunneling microscope”1 and since that time there has been an explosion of techniques and experiments that are based on the STM. STM is mostly used to image atoms, molecules, nanostructures and

surfaces, but more advanced systems also permit to move around atoms and molecules and to place them in specific locations on a surface to create 2D structures, and maybe nanomachines of the future. We have developed in our lab an inexpensive STM capable of atomic resolution at room temperature and atmospheric pressures eliminating the need for an expensive cryostat and vacuum pumps – the Low-Cost Room-Temperature Atmospheric-Pressure STM. The STM has been built by the PI and his students, along with Mark Plano Clark, Professor at Doane College, and his students. The STM has the potential to reach many students and encourage them to consider science, technology, engineering and mathematics (STEM) careers. Our goal for this new proposal period is to make use of this technology to perform research projects using this low-cost STM. Specifically, we will involve students in the synthesis and study of graphene. Graphene is a nanomaterial that was discovered only a few years ago, and this discovery was recently awarded with a Nobel Prize. Graphene has many outstanding mechanical and electrical properties which are currently subject to a large number of research activities. However, its most outstanding property is the simplicity with which graphene can be fabricated. The most established method is the "Sticky Tape Method", also called mechanical exfoliation, where sticky tape is applied to graphite and then pulled off quickly. The tape removes single layers of graphite, also known as grapheme. The flakes from the tape can then simply be applied to a substrate for further investigation. Graphene is easily seen in scanning tunneling microscopes, where its characteristic honeycomb structure is clearly visible even in air. The fabrication by exfoliation and imaging with STM is currently a hot topic in materials and nanoscience, and we plan to involve REU students in such research. During the 10 week summer project, students involved will learn about graphene as a new nanomaterial, will study its outstanding properties and will learn about recent research on graphene at UNL. The student will learn to fabricate graphene samples by exfoliation and will study those samples with our low-cost STM, helping to develop it as a tool for research.